tangential flow filtration diafiltration

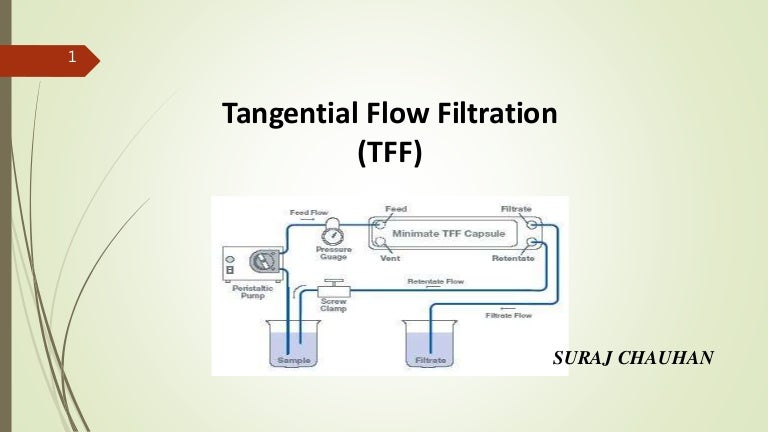

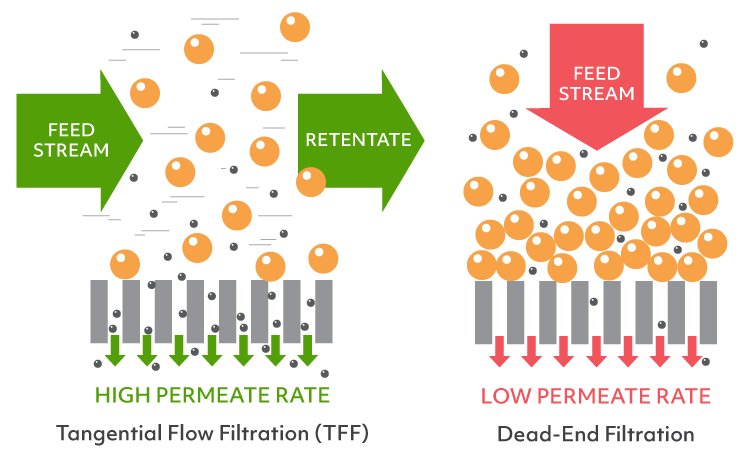

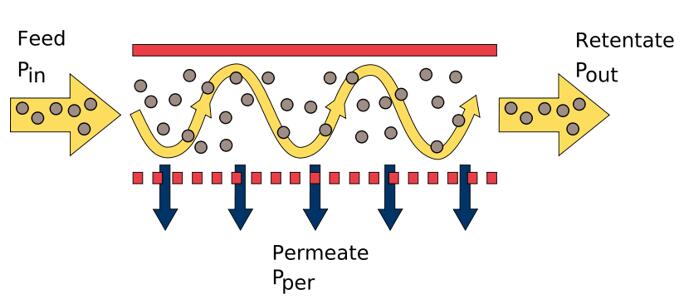

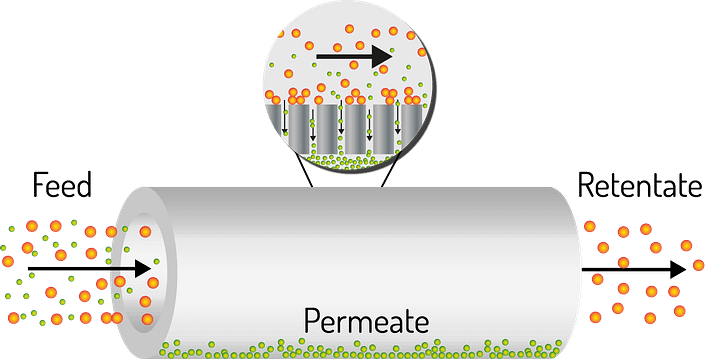

The solution flows tangentially across a membrane such that a selective part of the fluid permeates the membrane while the filtrated matter is retained increasing its concentration. Pall Scientific Technical Report.

Sample Concentration Diafiltration µpulse Tff System

Sibility of using a diafiltration centrifugal device DCD and a tangential flow filtration TFF system for purification of polylactide-co-glycolide PLGA nanoparticles containing PVA as an emulsifierstabilizer.

. An applied pressure serves to force a portion of the fluid through the membrane to the filtrate side. Concentration Increases the concentration of a solution by removing fluids while keeping the solute molecules. For all steps like cell harvest clarification perfusion diafiltration concentration.

As in NFF particulates and macromolecules that are too large to pass through the membrane pores are retained on the Pressure Filtrate Feed Flow. Tangential flow filtration is used in concentration and diafiltration processes. TFF can be used to concentrate and desalt sample solutions ranging in volume from 10 mL to thousands of liters.

The Global Tangential Flow Filtration Market is expected to grow at a significant pace with substantial growth rates over the estimated period. PURPOSE Membrane-based Tangential Flow Filtration TFF unit operations are used for clarifying concentrating and purifying proteins. Tangential flow filtration is commonly used in concentration and diafiltration processes.

An applied pressure serves to force a portion of the fluid through the membrane to the filtrate side. 4 FLUSHto remove NaOH solution. Applied to a wide range of biological fields such as immunology protein chemistry molecular biology biochemistry and microbiology.

Whether you are looking for a cost-efficient multi-use solution or a functionally closed solution with single. Our tangential flow crossflow filtration systems are engineered for low hold-up volume maximum volume concentration and optimal product recovery in single-use and multi-use applications from process development to large-scale manufacturing with compatible holders available for expendables. Its latest research report titled Global Tangential Flow Filtration Market offers a unique point of view about the global market.

Tangential Flow Filtration TFF also known as crossflow filtration is a quick and reliable method for separation and purification of media in biopharmaceutical processes. While there are many factors that contribute to final system design several key parameters should be optimized early in the process development phase. Protein Concentration and Diafiltration by Tangential Flow Filtration 4.

This technical brief is a practical introduction to protein processing using tangential flow filtration. These disposable tangential flow filtration devices accelerate and simplify scale-up bioprocessing applications. As in NFF particulates and macromolecules that are too large to pass through the membrane pores are retained on the Pressure Filtrate Feed Flow.

Pdf Protein Concentration And Diafiltration By Tangential Flow Filtration Semantic Scholar Presentation1 Tff. In ultrafiltration UF tangential flow filtration TFF systems operating parameter selection will have far reaching impact as the process is scaled to full-scale manufacturing levels. 1 INSTALLcassette with torque wrench.

In Tangential Flow Filtration TFF the fluid is pumped tangentially along the surface of the membrane. In contrast to standard tangential flow filtration equipment TFF the cross-flow is accomplished by movement of the filter. Cross-flow filtration CFF or tangential flow filtration TFF has proven as suitable downstream processing operation for virus and VLP processing Carvalho et al 2019.

This process is done by selecting a filter significantly smaller than the solute molecules to allow for a higher retention of solute molecules. Diafiltration DF is most often used to exchange product into a desired buffer eg from an elution buffer into a final formulation buffer UF and DF typically use tangential flow filtration where feed flows parallel to the membrane surface rather than perpendicular to the surface. This technical brief is a practical introduction to protein processing using tangential flow filtration.

Introduction to Tangential Flow Filtration for Laboratory and Process Development Applications 2. Grzenia Carlson. 5 MEASURENormalized Water Permeability NWP To determine membrane cleaning effectiveness.

Sartorius offers flexible tangential flow filtration systems for process development and clinical trials in laboratory environments as well as for commercial production batches. 3 SANITIZEfilter and system with NaOH solution. It can be applied to a wide range of biological fields such as immunology protein chemistry molecular biology biochemistry and microbiology.

Diafiltration Phillips Signs 2004 is desirable. Sartorius hollow fiber tangential flow filtration TFF modules provide high-performance separation in various upstream and downstream bioprocessing unit operations including cell harvest clarification perfusion diafiltration and concentration. In TFF also referred to as cross-flow filtration the.

Our systems are designed to meet the success criteria for purification by tangential. Tangential Flow Filtration Holders Systems. A Fast Efficient Method for Desalting or Buffer Exchange of Biological Samples PN 33289.

Benefiting from our leading bioprocess knowledge and engineering expertise in tangential flow filtration TFF we have developed multi-use single-use and process development systems incorporating many unique innovative and intelligent features. Tangential flow filtration TFF is a rapid and efficient method for separation and purification of biomolecules. It is intended to help scientists and engineers achieve their protein processing objectives by discussing.

Process Solutions for Ultrafiltration and Diafiltration. 2 FLUSHto remove storage agent. Membrane-based Tangential Flow Filtration TFF unit operations are used for clarifying concentrating and purifying proteins.

Tangential flow filtration TFF is a rapid and efficient method for separation and purification of biomolecules. Plug in a Minimate TFF capsule add sample and turn on the pump to start processing. It is mainly used for robust applications as it is known for its durability and is very economical.

Tangential flow filtration TFF is a chemical unit operation used to purify and concentrate liquid suspensions of colloids proteins or cells. In contrast to other forms of filtration which media is passed through a membrane as the name. MEASUREhold-up minimum working volumes.

It is intended to help scientists and engineers achieve their protein processing objectives by discussing how the choice of key components. Materials of construction for UFDF membranes. Ad Sartorius hollow fiber provides high-performance in upstream and downstream separation.

In Tangential Flow Filtration TFF the fluid is pumped tangentially along the surface of the membrane.

How It Works Hollow Fiber Tff Tangential Flow Filtration Youtube

What Is Tangential Flow Filtration Tff And Where Is It Used Tbl Plastics

Figure 7 From Protein Concentration And Diafiltration By Tangential Flow Filtration Semantic Scholar

Schematic Diagram Of Diafiltration And Ultrafiltration Using Either A Download Scientific Diagram

Tff Based Ultra Filtration In A Concentration Mode And B Download Scientific Diagram

Ultrafiltration Diafiltration Uf Df Managing Aggregates In Your Monoclonal Antibody Mab Process Youtube

Tangential Flow Filtration Tff Gfp Purification Part 5 Of 6 Youtube

Diafiltration Purification And Concentration Schematic Shown In This Download Scientific Diagram

Figure 3 From Protein Concentration And Diafiltration By Tangential Flow Filtration Semantic Scholar

Figure 1 From Protein Concentration And Diafiltration By Tangential Flow Filtration Semantic Scholar

Pendotech Cross Flow Filtration Tff System Pendotech

Tangential Flow Diafiltration Tfd Procedure Sample Water Is Pumped Download Scientific Diagram

Custom Tff Diafiltration Service

What Is Tangential Flow Filtration And How Can It Benefit Your Process